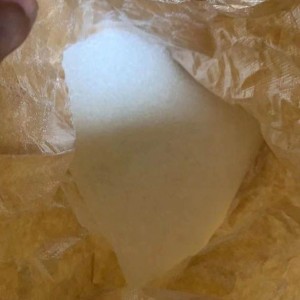

Los ntawm kev xaiv cov monomers tshwj xeeb, ib tus tuaj yeem ua tiav ib qho crystallizable thiab pob tshab polyamide mus tas li.Cov crystallites me me heev uas lawv tsis tawg lub teeb pom kev, thiab cov khoom zoo li pob tshab rau tib neeg lub qhov muag - ib qho cuab yeej hu ua microcry stallinity.Vim nws cov crystallinity, cov qauv microcrystalline khaws cov khoom tseem ceeb xws li kev ntxhov siab tawg ua haujlwm - tsis muaj huab cua.Lub degree ntawm crystallinity yog li negligible, txawm li cas los xij, uas nws tsis muaj kev cuam tshuam rau tus cwj pwm shrinkage ntawm molded qhov chaw.Nws tau txais ib qho zoo li isotropic shrinkage zoo li amorphous cov ntaub ntawv.

Nws yog ib qho tsis muaj kuab paug, pob tshab mus tas li polyamide rau kev txhaj tshuaj molding.